1) Trade tools and mobile work areas

Grinders, saws, compressors, welders, chargers and portable equipment often move around the site. In these scenarios, portable or trailer-mounted generators are popular because they’re practical and flexible.

2) Site sheds, offices and amenities

Site compounds need steady power for air conditioning, IT, lighting, fridges, kettles and security. For longer durations, you may need to consider whether diesel-only, hybrid, or mains connection makes the most sense.

3) Lighting for safety and extended work hours

Lighting towers are common on civil works, roadworks and night shifts. Many modern lighting towers focus on fuel efficiency, long runtimes and easier monitoring/controls.

4) Plant, pumps and higher-demand equipment

Pumps, large compressors, hoists and site infrastructure can introduce high starting loads and require stable voltage under changing demand.

Diesel, solar, hybrid or mains: which power option fits your project?

One competitor does this particularly well: RhinoSite frames the decision around project duration, power demand, location and sustainability requirements, then compares diesel, solar, hybrid and mains pros/cons.

Here’s a simple, construction-friendly version:

- Short-term + high demand: diesel is often the quickest and most straightforward.

- Long-term compounds: mains connection (if available) can reduce operating costs.

- Noise-sensitive or sustainability-driven sites: hybrid/BESS solutions can cut generator run time and fuel usage.

- Remote sites: diesel-only or diesel + hybrid is common.

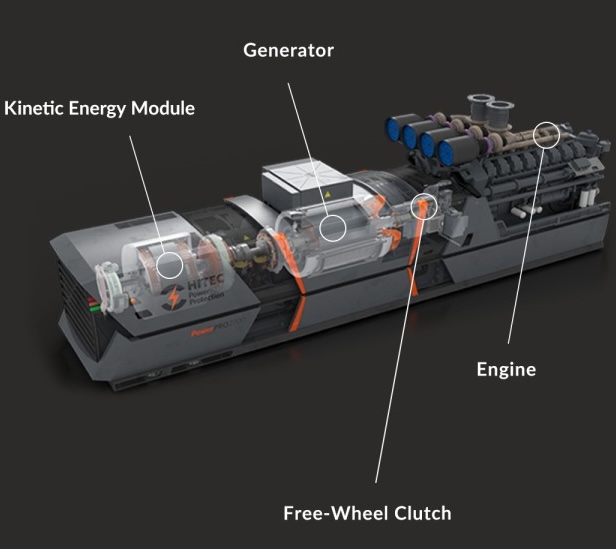

Hybrid systems are increasingly discussed in construction because they can reduce generator runtime and fuel dependency (and noise), while still providing continuity of power.

What to look for in a construction-ready generator

Competitors repeatedly mention “built for construction use” features like user-friendly controls, weather resistance, and engineered options (silencing, control panels, synchronising).

Here’s what that means in practical terms:

Rugged enclosure and site durability

Dust, vibration, weather exposure, forklift movement — construction equipment needs heavy-duty protection.

The right phase: single-phase vs three-phase

- Smaller tool and amenity loads may be single-phase.

- Many site and plant loads require 3 phase.

Stable power delivery (especially for mixed loads)

Construction sites don’t have smooth, consistent demand. Voltage stability matters, particularly when motors start and stop.

Practical deployment

Trailer-mounted, skid-base, bunded tanks, easy access panels — these details reduce setup time and service headaches

Typical specifications for construction diesel generators

Below is a general “what you’ll commonly see on site” technical overview. Exact specs vary by model and duty cycle.

| Specification | Typical Range / Detail | Why it matters on construction sites |

|---|---|---|

| Power output | 10 kVA – 500 kVA+ | Scales from tools/site sheds to larger plant loads |

| Phase type | Single / Three phase | Three phase often required for site infrastructure |

| Fuel type | Diesel | Strong torque, long runtime, reliable supply options |

| Engine speed | 1500 RPM (50 Hz) | Better longevity and efficiency for long shifts |

| Alternator type | Stamford / Leroy Somer (or equivalent) | Helps maintain stable output under variable loads PR Power |

| Control panel | Digital controller with alarms | Easier monitoring and fault response |

| Enclosure | Silenced, weather-protected | Reduces noise and protects components |

| Runtime | Typically 8–24+ hours (tank dependent) | Fewer refuels, less downtime |

| Mounting | Skid / trailer | Faster mobilisation between stages |

Generator hire vs buying for construction

Many projects prefer generator hire or a rental generator for:

- short-term works,

- seasonal peaks,

- shutdowns,

- emergency replacement while a unit is serviced.

Other builders prefer owning units for repeat work across multiple jobs. Some also choose used generators for sale as a cost-effective option where duty cycle and service history make sense (especially for predictable loads and scheduled maintenance).

If you’re unsure which direction is best, our team at All Generators Australia can help map your duty cycle and recommend the most practical path.

Common construction generator mistakes (and how to avoid them)

1) Under-sizing because you only count “running watts”

Motor starting loads (pumps, compressors) can spike. Under-sizing leads to nuisance trips, unstable voltage, and equipment stress.

2) Ignoring distribution and cabling

A generator is only as good as the way power is distributed. Plan boards, leads, protection, and layout early.

3) No fuel and servicing plan

Long projects need predictable refuelling and preventative servicing to avoid failures at the worst time.

4) Noise and placement issues

If you’re near residential areas, silencing, placement, and (sometimes) hybrid options can make a big difference.