When you design a new data center, it’s often with immediate project goals in mind, such as meeting current capacity demands and staying within budget. However, forward-thinking designs also take into account the facility’s long-term operational health.

Don’t commit to a design that will only make future repairs difficult and expensive. Explore the value of modular data center design for maintainability, uptime, efficiency and longevity to reduce your long-term risks and costs. Learn how to design your space for easy maintenance and system health.

Prioritize layout for accessibility

Create a navigable data center layout to support maintenance needs. By providing clear aisle spacing and accessible pathways, you can reduce downtime and delays as technicians perform routine tasks and replace equipment uninterrupted.

Per the TIA-942 standard, data centers should establish a minimum of 2 feet of rear clearance and 3.3 feet of front clearance to support accessibility. Lay out your floor plan accordingly, and take additional measures to protect your infrastructure, including:

● Dusting and sweeping to clear paths for maintenance and prevent equipment overload

● Stockpiling tools and replacement parts in convenient locations to expedite repairs and maintenance

Hot Aisle/Cold Aisle Containment

Take the extra step to reduce data center maintenance needs by regulating the environment. Follow American Society of Heating, Refrigerating and Air-Conditioning Engineers guidelines for airflow management, alternating hot and cold aisles to save energy and keep equipment from overheating. Cool your equipment by directing cool air to the front of the servers, then release warm air out the back and into the hot aisle to be recycled by the system.

Be sure to mind the temperature throughout the process. The safest range is generally 65-80 degrees Fahrenheit at the intake, and you can monitor and adjust as needed. Save power by installing sensors that measure temperature at the equipment intake and use variable speed fans to adjust based on real-time needs.

Implement modular design

Add an extra layer of confidence to your data center design. Modular construction with fully engineered, prefabricated components provides an all-in-one solution that supports easy system upgrades.

Scalability Without Major Overhauls

Adopting a modular data center design supports both maintainability and scalability. This allows you to minimize stranded capacity by only investing in the infrastructure you currently need but remain flexible to integrate new modules and technologies without retrofitting later.

Construction Efficiency

Make your data center match your needs. A modular approach strengthens construction efficiency by integrating components into an optimal footprint. By using standardized modules and procedures, data centers bypass traditional construction requirements to trim time to completion up to 30% and reduce on-site labor requirements.

Standardize and label infrastructure.

Keep track of what requires your attention the most. With a combination of labeling and asset tracking, your data center can better execute data collection and equipment maintenance.

Consistent Labeling for Power, Networking and Cooling Systems

TIA-942 requires consistent labeling to keep infrastructure traceable and organized. Make it easier for technicians to identify cables, racks and equipment during maintenance tasks to expedite maintenance and reduce downtime with easier troubleshooting and quicker system upgrades.

DCIM Tools for Accurate Asset Tracking

Simplify capacity planning and centralize important records with data center infrastructure management (DCIM) tools. Achieve advanced visualization, reporting and analytics to track changes in your data center and unlock a source of truth. DCIM tools integrate with your building management, IT systems management and virtualization management to sync information with other groups.

Consider redundancy and fault tolerance.

Building a data center with redundant systems and fault tolerance ensures high availability and enables repairs without disrupting operations. Improve reliability by integrating physically separated pathways, multiple service providers and redundant networking equipment. Redundant power setups and backup generators protect against outages by providing extra power supplies, cooling units and network connections.

N+1 or 2N Redundancy for Critical Systems

Protect your data center in one of two ways: by implementing N+1 or 2N redundancy.

● N+1 redundancy gives you one extra component for every critical system. By planning for N+1, a data center can service a single failure without downtime.

● 2N redundancy provides full redundancy with two independent systems. If one fails, the other can take over to avoid power and service disruption.

Pathways for Maintenance Without Downtime

Achieve Tier III status as defined by the Uptime Institute and implement design pathways that support constant availability and smooth performance. Tier III data centers are designed for concurrent maintainability, so any component can be taken offline for maintenance or replacement without disrupting operations.

Ensure continuous service without shutdowns by adding redundant pathways and high-speed connections.

Take cooling systems into account.

Data center cooling is critical as computing requires increasingly heavy thermal loads. Protect your operational efficiency and cooling infrastructure with targeted enhancements that support your modular data center design.

Isolated Maintenance Paths

Design your cooling systems to include isolated maintenance paths for computer room air conditioning (CRAC) units and liquid cooling systems.

● CRAC units use chilled water and air to maintain a set temperature, airflow and humidity in the data center.

● Liquid cooling systems pump water through coils to absorb heat from components, lower the temperature and reduce energy costs.

Monitoring Sensors

Predict and prevent failures before they even begin. Maintaining a relative humidity between 45-55% keeps equipment safe but may be difficult to track. Install Internet of Things sensors to not only monitor these environmental factors inside your data center but also to maintain a consistent climate and reduce equipment wear and tear.

● Temperature sensors alert staff if it gets too warm or cool.

● Humidity sensors prevent condensation and static electricity.

● Airflow sensors prevent overheating.

Account for power systems.

Data centers are designed to keep running, even during outages. A well-planned modular data center design achieves this by implementing several pieces of infrastructure. Keep yours running by accounting for:

Power Distribution Units (PDUs)

PDUs act like smart power strips for servers. Control and monitor electricity across multiple machines and even manage the power supply remotely to prevent overuse.

Uninterruptible Power Supplies (UPS)

Outage in the main power supply? UPS keep servers running as backup generators start up to prevent downtime.

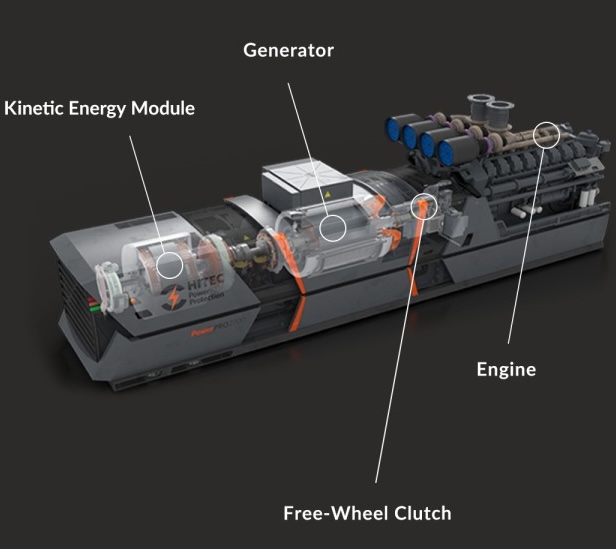

Generators

Save your data center from costly outages. Generators provide backup power across systems until normal power resumes.

Proper Grounding and Cable Organization

Prevent electrical faults and equipment damage. Grounding enables individual components to be connected or removed without disruption. By separating power and data cables, you can avoid interference for more reliable performance.

Implement documentation and maintenance protocols.

Documentation guides effective maintenance right alongside team expertise. Keep equipment information organized to understand how to service your equipment.

Add Maintenance Data to Facility Management Systems

Collate equipment data, such as serial numbers and maintenance histories, so technicians can quickly find what they need for repairs or upgrades. With this level of detail, you can create clear records that make it easier to:

● Identify recurring issues.

● Improve maintenance schedules.

● Meet compliance requirements.

Design for proactive maintenance

Incorporating proactive maintenance strategies as part of modular data center design can significantly extend the life of your equipment and reduce operational costs. Choose from three key approaches to move from reactive to proactive maintenance:

Preventive Maintenance

Complete regular, scheduled checkups across the data center, even if nothing seems wrong. By engaging in preventive maintenance, you can avoid problems in their early phases or before they even begin.

Reliability-Centered Maintenance

Focus on your highest priorities by assessing critical systems first. By infrequently checking less important equipment, you can save time and money.

Predictive Maintenance

Deploy sensors and data analysis to spot potential failures before they happen. By assessing real-time conditions, you fix problems only when needed.

Optimize your data center

The most thoughtful and effective modular data center design reduces operational risks and maintenance costs. Maximize your long-term ROI by combining ease of access, modularity and monitoring. Collaborate early and often with operations teams during the design phase to ensure maintainability is built in.

Considering a modular data center design for your operation? Learn more by downloading our e-book, Embracing Modularity: Powering the Future of Data Center Construction.